Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

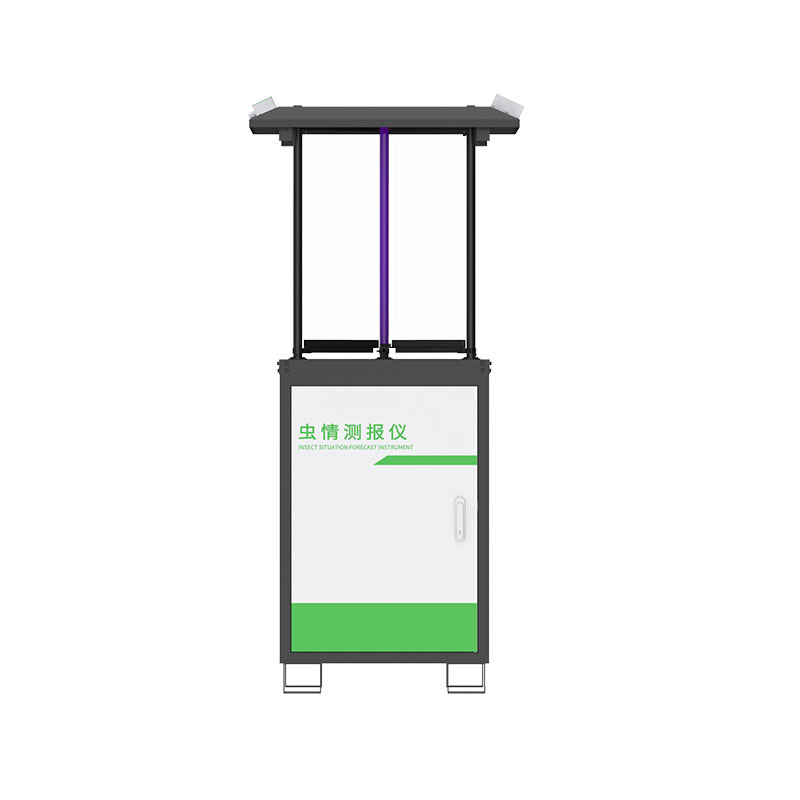

Model:FT-CQ1

Brand:tianyi

1.Introduction to Insect monitoring products

Insect monitoring enables real-time insights into pest population dynamics, providing the latest solutions for insect population monitoring and control.

Name: Insect monitoring

Comply with the standards: Comply with the GB-T24689.1-2009 standard image insect information measurement and reporting tool.

Main purpose: to analyze and predict the occurrence and development of pests, provide services for modern agriculture, and meet the needs of insect situation prediction and specimen collection.

Working principle: Using modern optical, electrical, CNC and other technologies, we realize high-temperature insect killing of insect traps, conveyor belts and automatic operation of the whole lamp.Under unsupervised conditions, system operations such as insect luring, insect killing, insect dispersion, photography, transportation, collection, and drainage can be automatically completed, and then wireless transmission technology and Internet of Things technology can be used to upload environmental meteorological and pest situations to the designated agricultural cloud platform in real time.

2.Insect monitoring main structure

Main machine material: spray plastic

The whole machine size: 717mm*727mm*1569.2mm.

Components: insect trapping device, impact screen, insecticide device, high-definition camera, main control system, mechanical components, rain and snow sensor, light sensor, professional metal box frame

3.Technical parameters of Insect monitoring

Operating system: microcontroller

Power supply method: 220VAC is standard, and solar power can be optionally supplied.

Equipment power consumption: The whole machine power consumption: ≤200W; standby power consumption ≤25W;

Working environment: 0~70℃, 0~85% (relative humidity), no condensation

Insulation resistance: ≥2.5MΩ (leasing protection)

Insect luring device: the default optical insect luring principle, and the principle of drug insect luring can be selected.Optical insect luring uses a 20W black light tube with a main wavelength of 365nm, and the starting time of the lamp tube is ≤5S.

Impact screen: It is made of high-transparent glass material, with a 120-degree angle between each other.The single screen size: 595±2mm long, 213±2mm wide, and 5mm thick.

Insecticidal device: The upper and lower far infrared insect body treatment chambers have a mortality rate of no less than 98%, and the completion rate of the insect body is not less than 95%.After working in the far-infrared insect body treatment chamber for 15 minutes, the temperature can reach 85℃±5℃.

High-definition camera: This device supports a 500W pixel camera, and the camera is plugged in and plugged in, making it convenient for on-site replacement.The camera can collect the insect situation on the conveyor belt in real time, and the clarity of the captured image can meet the requirements of artificially identifying insect species.

Main control system: The main control system can provide Bluetooth APP configuration tools and supports Bluetooth contactless configuration.Supports changing the device's working mode and individually controls the start and run of each component of the device.Supports remote upgrade programs, base station positioning, automatic timing calibration, and setting parameters through Bluetooth configuration APP.

Communication method: Supports 4G communication, optional Ethernet RJ45 communication.

Mechanical components: The inside of the box contains insect rain baffle, insecticide baffle, dry baffle, vibration device, insect transfer device, fill light, camera and other mechanical devices and control and execution equipment.

The Insect monitoring vibration device can vibrate the collected insects, so that insect conflicts evenly sprinkle and lay them on the conveyor belt, avoiding the accumulation of insects, ensuring that each insect body can be photographed clearly, and in conjunction with the platform software AI analysis and identification system, it can ensure that the insects collected during different time periods are not confused.

Rain control technology: The weather conditions on site are detected through rain and snow sensors.No rain and snow weather operates normally, and rain and snow weather stops operating.After identifying rainy and snowy weather, control the opening and closing direction of the insect rain baffle to achieve insect rain separation.

Light control technology: Detect the on-site light intensity through a light sensor, and is not affected by instantaneous strong light.When the light is less than the program set value, the control device operates normally; when the light is greater than the program set value, the control device stops running.

Time control technology: can set the work start time, working time, single working cycle time, insect-induced light turn on, delay turn on after rain, etc.

Work mode: Supports automatic working mode, manual working mode, and supports working mode switching.

Automatic working mode workflow: Flying insects are attracted by the light source of insects → enter the blinds → crash into the impact plate → fall into the insecticide warehouse after impact → kill the insects at high temperature → turn the insect baffle over → the insect corpse into the drying warehouse → drying warehouse for high temperature drying, after drying is completed → turn the drying baffle over → the insect corpse drops on the vibrating plate → start the vibrating plate → the insect corpse is flat on the conveyor belt → the conveyor belt will transport the flying insect corpse to the camera → take a photo → upload the photo to the server.

Introduction to manual working mode: Supports the control of the operation of various mechanical components through Bluetooth configuration APP, cloud platform, and insect monitoring APP.

4.Insect monitoring installation method:

1.Choose the installation location of the insect detection cabinet, prefabricate the flat and hard cement platform as early as possible, and then drill holes according to the fixed size of the base.

2.Use the expansion screws in the accessories to install them into 8 holes.

3.Correlate the 8 expansion screw holes of the four corners under the equipment support column and tighten and fix them with a wrench.

5.Insect monitoring insect information reporting platform:

1.The insect information reporting platform can log in and manage separately according to different permissions, and can at least allocate accounts with different permissions above 8 levels.

2.The insect information monitoring platform remotely checks the current working status of each component of Insect monitoring, and the status can be stored to view history records.

3.Users of the insect situation measurement and reporting platform can increase the types of pests.

4.The statistical chart of the insect situation measurement and reporting platform has two ways of changing pests by region and time.This includes a bar chart and a line chart.

5.The insect situation measurement and reporting platform uses the second-generation insect situation database for automatic AI analysis, and users can supplement and correct the AI analysis results by themselves.

6.The insect information measurement and reporting platform supports secondary development, and provides professional insect information measurement and reporting platform and APP client for free.The platform can provide API interfaces.It can provide SDK development interfaces based on java and C#.

In numerous meteorological monitoring and related fields, accurately measuring wind speed and direction is of great significance. From the perspective of large-scale meteorological research, understanding accurate data of wind speed and direction helps meteorological departments better predict weath...

With the vigorous development of smart agriculture, the four aspects of agricultural condition monitoring have become a key driver in advancing the modernization of agriculture. So, what exactly are these four aspects of agricultural condition monitoring in smart agriculture? In fact, they include s...

A Water Quality Monitoring Buoy is an on-site water quality testing device installed in water areas such as rivers, lakes, reservoirs, and coastal waters. It is mainly used in fields like the implementation of the river chief system and the construction of sponge cities. It can conduct continuous an...

Negative oxygen ion monitoring stations function to real-time capture and transmit negative oxygen ion data in the air. Through "on-site display + remote viewing," they convert the originally invisible and intangible negative oxygen ion concentration into intuitive data, allowing managers...