Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-08-01 08:49:00 source:Weather Station viewed:189 time

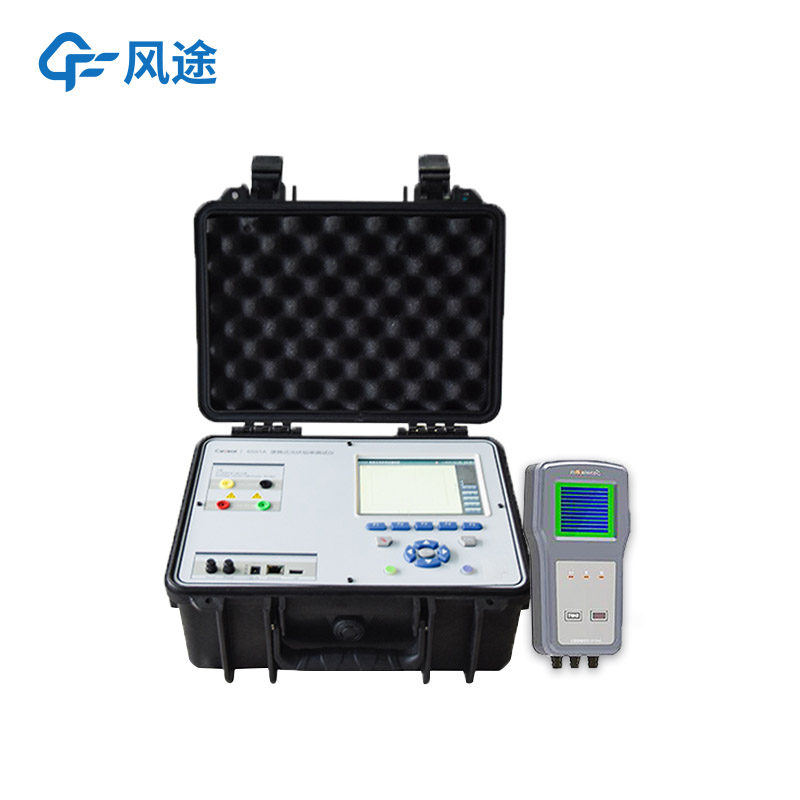

In the daily operation and maintenance of photovoltaic power plants, testing equipment is a key tool to ensure power generation efficiency and system stability. Among them, the EL detector and I-V Curve Tracer are two widely used professional devices that evaluate the performance of photovoltaic modules and systems from different perspectives.

The EL detector is mainly used to detect hidden defects inside photovoltaic modules. Its working principle is based on the electroluminescence phenomenon: when the module is excited by a reverse voltage, the internal semiconductor materials will emit infrared light of a specific wavelength. By capturing the distribution of this light with a high-sensitivity infrared camera, abnormal areas inside the module can be intuitively presented. For example, problems such as hidden cracks, cold soldering, and broken grids in the solar cells will cause local weakening or disappearance of luminescence intensity, forming obvious dark spots or dark lines in the imaging. If such defects are not found in time, they will gradually expand over time, affecting the power generation efficiency of the module and even causing the hot spot effect, which will cause irreversible damage to the entire module. EL detection is usually carried out in the module production process, before power plant installation, and during regular maintenance. It can effectively screen out modules with potential problems and prevent unqualified cells from affecting the overall performance after entering the power generation system.

The I-V Curve Tracer focuses on evaluating the electrical performance parameters of photovoltaic modules or photovoltaic systems. It measures the current-voltage relationship of the module at different operating points by simulating different light intensity and temperature conditions, and generates a complete IV curve. From this curve, parameters such as open-circuit voltage, short-circuit current, maximum power point voltage, and maximum power point current can be obtained, which directly reflect the power generation capacity of the module. In practical applications, IV detection can help technicians judge whether the module meets the design standards and identify performance degradation caused by aging, shading, pollution and other factors. For photovoltaic power plants, regular IV detection of arrays can timely find component strings with abnormal performance, provide a basis for targeted maintenance, and ensure that the power generation efficiency of the entire power plant is in the best state.

In short, although the EL detector and I-V Curve Tracer have different functions, they complement each other in the quality control of photovoltaic power plants. EL detection focuses on the internal physical defects of components to eliminate hidden dangers from the source; IV detection evaluates the actual working capacity of components from the perspective of electrical performance to ensure power generation efficiency. The combined use of the two provides comprehensive technical support for the long-term stable operation of photovoltaic power plants and is an important means for the photovoltaic industry to ensure power generation quality and reduce operational risks.

The 7-element miniature sensor includes monitoring modules for temperature, humidity, air pressure, illumination, wind speed, wind direction, etc., with a mounting bracket customized according to the street lamp structure. It can be installed at a rain-proof and ventilated position in the upper midd...

Global Navigation Satellite System (GNSS) is an autonomous, worldwide space-based positioning system. These systems continuously broadcast radio navigation signals to the ground through satellite constellations, providing users with positioning, navigation, and timing services.01 GNSS Technica...

Agriculture, as the foundation of human survival, is intricately linked to the weather. Weather conditions profoundly influence every aspect of agricultural production. During the sowing stage, seed germination requires suitable accumulated temperature, typically above 10°C. If the temp...

The IV curve, or current-voltage curve, visually demonstrates the current output of a photovoltaic (PV) cell or module at different voltages. Through this curve, core parameters such as open-circuit voltage, short-circuit current, and maximum power point can be obtained. These parameters are crucial...