Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

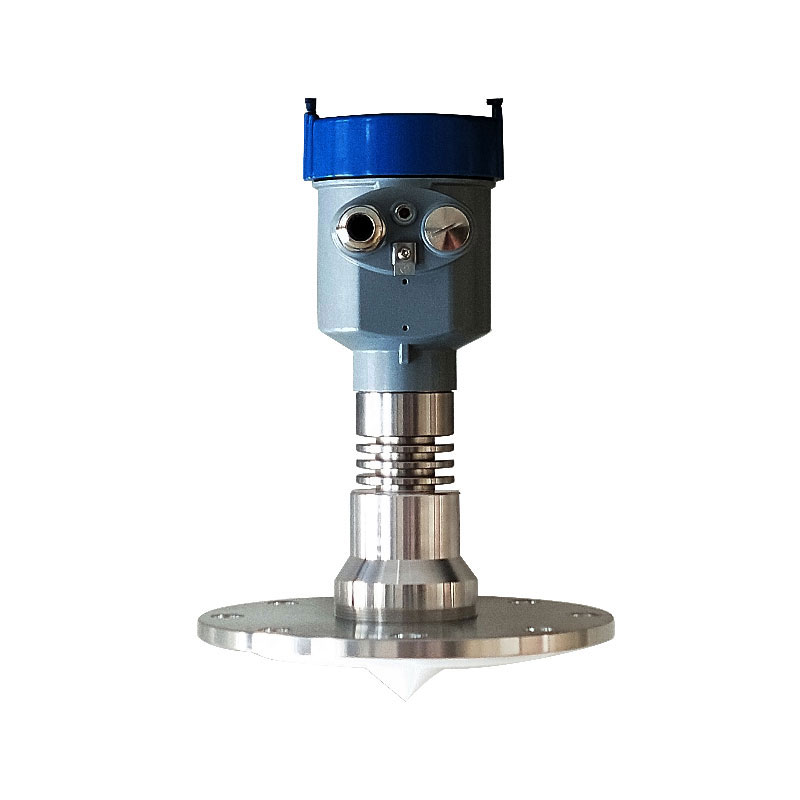

Model:YW-26B

Brand:tianyi

1.Corrosive liquid level sensor product principle

Corrosive liquid level sensor is a non-contact, continuous ultrasonic liquid level sensor that is ideal for measuring hot, corrosive liquids and sewage.The radar level antenna emits narrower microwave pulses and transmits them downwards through the antenna. After contacting the surface of the medium to be tested, the microwave is reflected back and received by the antenna system again. The signal is transmitted to the electronic circuit part and automatically converted into a level signal (because the microwave propagation speed is extremely fast, the time it takes for the electromagnetic wave to reach the target and return to the receiver through reflection is almost instantaneous).

2.Corrosive liquid level sensor technical parameters

Product Features: Tetrafluoroconical antenna

Typical applications: liquids, powders, high sanitary levels, easy crystallization, condensation, easy adhesion of oil smoke and dust, etc.

Measuring range: 30 meters

Antenna material: PTFE (optional)

Accuracy: ±5mm

Process temperature: -40~260℃

Process pressure: -0.1~4.0Mpa

Power supply: 24vDC (two wires, four wires)

Signal output: 4~20mA/Har (two wires/four wires)

RS485/Modbus

Process connection: flange (≥DN50 optional)

Protection level: IP67

Frequency range: 26GHz

Protection level: IP67

Explosion-proof grade: ExiaⅡC T6 Ga/Exd ia IIC T6 Gb

On-site display: LED (standard)

Cable entrance: M20*1.5, ½NPT (optional)

Housing material: cast aluminum, 304 stainless steel (optional)

3. Corrosive liquid level sensor product features

The antenna is small in size and is easy to install; non-contact radar, no wear and pollution.

Almost not affected by corrosion and foam; almost not affected by changes in water vapor, temperature and pressure in the atmosphere.

Severe dust environments have little impact on the high-frequency level gauge operation.

Shorter wavelengths and better reflect on slanted solid surfaces.

The beam angle is small and the energy is concentrated, which enhances the echo capability while also helps avoid interference.

The measurement blind spot is smaller, and it will also achieve good results for small tank measurements.

High signal-to-noise ratio allows better performance even in fluctuations.

High frequency is the best choice for measuring solid and low dielectric constant.

Road Weather Sensors is a professional optical instrument that estimates meteorological optical range by measuring the scattering intensity of light particles in the atmosphere. This device monitors the concentration of particles such as smoke, dust, haze, and fog, converting the atmospheric extinction coefficient into visibility data. It is widely used in meteorological monitoring, traffic management, and maritime applications....

Ultrasonic Portable Mini Wind Meter is a meteorological instrument used to measure air flow speed and direction. It consists of two parts: a wind speed and direction sensor and a data display unit....

In the agricultural field, the traditional extensive irrigation method relying on experience is likely to cause either water resource waste or insufficient irrigation. With the rise of precision agriculture, different crops have varying requirements for soil temperature and humidity at different gro...

Modern agriculture is transitioning from extensive management to precision agriculture and smart agriculture. Data-driven decision-making is employed to achieve the goals of water conservation, fertilizer reduction, pesticide reduction, yield increase, and quality improvement. Meteorological data is...