Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-10-09 08:56:21 source:Weather Station viewed:208 time

In the photovoltaic industry, requirements for module quality and reliability are becoming increasingly stringent. Traditional inspection methods cannot effectively identify internal defects, making EL (Electroluminescence) defect detection technology an indispensable quality control tool in photovoltaic manufacturing and operation.

EL detectors operate based on the principle of electroluminescence: when a forward bias voltage is applied to crystalline silicon solar cells, carrier recombination emits near-infrared light. The system captures these light signals through a high-sensitivity infrared camera to generate images reflecting the internal state of the module. Defective areas appear as dark regions, dark spots, or dark lines.

Detection content includes:

Microcracks and cracks, appearing as linear or irregular dark lines

Broken grids and cold solder joints, appearing as discontinuous dark lines or local brightness attenuation

Black heart cells, showing concentric circular dark areas spreading from center to edge

Short-circuited black cells, appearing as completely black cells in imaging

PID effect, characterized by darkening at the edges

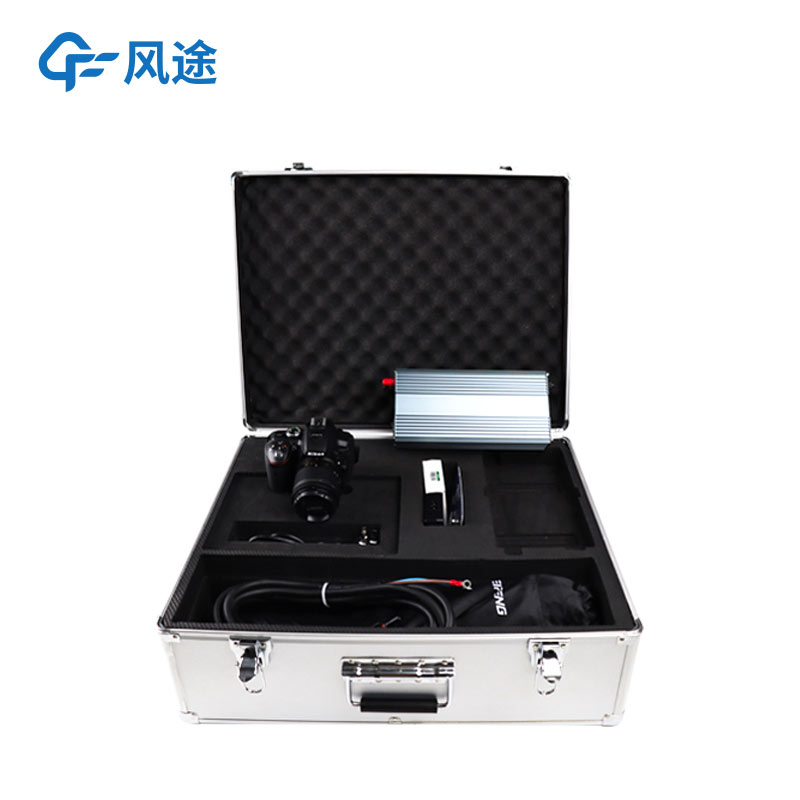

Portable EL detectors feature lightweight, modular designs, generally weighing less than 5 kilograms, equipped with foldable stands, wireless transmission modules, and portable power supplies, suitable for on-site inspection and mobile work scenarios. In photovoltaic power plant construction, portable EL detectors are widely used for component acceptance testing to ensure component quality meets standards before installation. During power plant operation and maintenance, operators can directly inspect installed components on the mounting racks without disassembly, enabling rapid localization of problematic components. Modern portable EL detectors are often equipped with high-resolution infrared cameras of 24 million pixels or higher, with imaging precision reaching 0.1mm/pixel. Combined with wireless control and real-time imaging capabilities, they can inspect 800-1000 modules per day, significantly improving on-site inspection efficiency.

Agricultural meteorological disasters pose enormous threats to agricultural production. During droughts, prolonged water shortage causes soil to dry out, stunting or even killing crops. In severe cases, large-scale crop failures or even total harvest losses occur, with scenes of cracked land and no...

In high-risk industries such as chemical plants, production safety is not only crucial for business operations but also directly related to personnel safety and environmental protection. These locations often contain flammable and explosive gases or dust, where conventional weather monitoring equipm...

With the vigorous development of smart agriculture, the four aspects of agricultural condition monitoring have become a key driver in advancing the modernization of agriculture. So, what exactly are these four aspects of agricultural condition monitoring in smart agriculture? In fact, they include s...

Have you ever wondered why the air feels especially fresh near forests and waterfalls? This is due to the difference in negative oxygen ion content in the air. Now, TianYi's FT-FY1 Negative Ion Detector makes this "freshness" measurable and quantifiable, providing accurate data support...