Tianyi Sensor IOT Technology Co., Ltd

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

Sales Manager:Ms. Emily Wang

Cel,Whatsapp,Wechat:+86 15898932201

Email:info@fengtutec.com

Add:No. 155 Optoelectronic Industry Accelerator, Gaoxin District, Weifang, Shandong, China

time:2025-11-05 08:51:03 source:Weather Station viewed:317 time

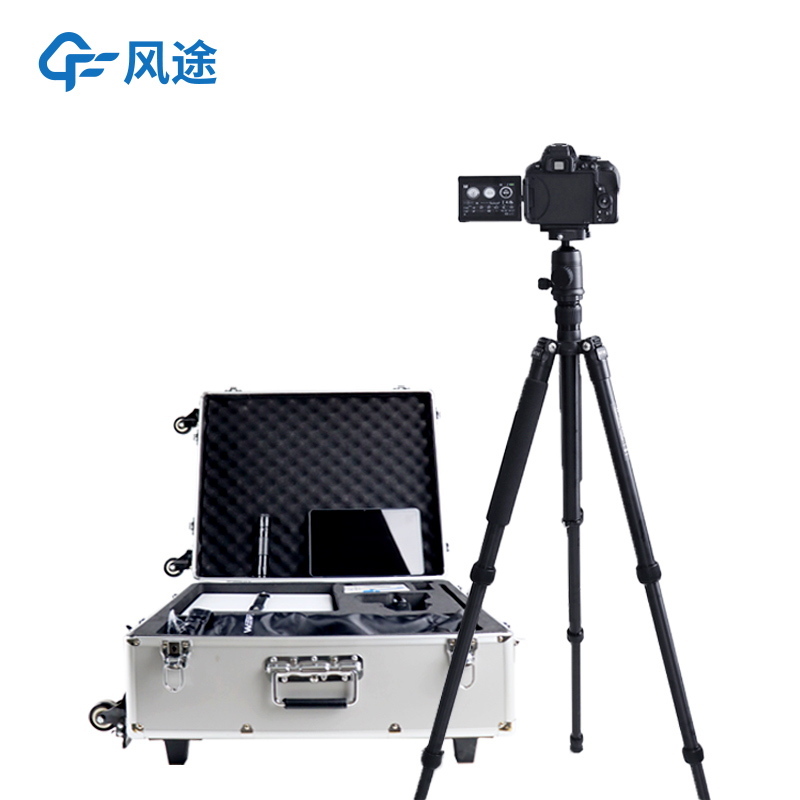

TianYi® EL Detector [Model: FT-EL1] Partial Parameters:

Detectable Defect Types: Cracks, broken cells, fragments, broken grids, black core, poor soldering, process contamination, low-efficiency cells, black edge, over-firing, over-etching, perforations.

Camera: 20-megapixel; Resolution: 4496 x 3000; Sensor: 23.6x15.6mm CMOS.

Detection Area: 3000mm * 2000mm.

Lens: 18-55mm.

Mount: Integrated mount, 1.85-meter aluminum alloy stand.

Weight: 5kg.

During the long-term operation of photovoltaic (PV) power generation systems, solar cells may develop internal damage due to material defects, manufacturing process issues, or external stress, leading to issues such as micro-cracks, cell fragments, and PID effects. These defects are often invisible in their initial stages but can reduce the power generation efficiency and long-term reliability of the cells. To ensure the quality and performance of PV modules, effective detection methods must be employed during both the production process and power station operation and maintenance. Electroluminescence (EL) imaging technology has emerged as a crucial method developed to address this need.

The EL detector is a professional diagnostic device that operates based on the principle of electroluminescence. The principle is as follows: a forward bias voltage is applied to the PV module, injecting non-equilibrium carriers. This prompts electron-hole recombination within the cell, releasing energy in the form of photons and generating near-infrared light with a wavelength of 1100-1200 nanometers. Since the luminescence intensity is directly related to minority carrier lifetime and current density, areas with defects exhibit reduced recombination efficiency, appearing as dark spots or areas of abnormal brightness in the captured image. This allows for the diagnosis of potential defects within the PV module.

The equipment consists of four main systems:

The Excitation Source Unit is responsible for providing an adjustable DC bias power supply, enabling the module to operate in a non-grid-connected state.

The Optical Acquisition Unit includes a high-sensitivity CCD or CMOS camera sensitive to the near-infrared spectrum, coupled with a specific optical lens.

The Image Processing System utilizes specialized algorithms to enhance the signal-to-noise ratio and analyze image features.

The Structural Mount is designed as either a mobile or fixed installation structure, depending on the application scenario.

Regarding the functions of the EL detector, its primary role is defect identification. It can precisely detect micro-defects such as dislocations and cracks within the silicon material, broken grids and poor soldering at printed grid lines, and leakage channels at the cell edges. Secondly, it enables quality grading by analyzing the uniformity of the EL image and defect density, allowing for the classification of cells and modules into different quality grades. Finally, it provides operational support by conducting pre-installation inspections during the power station construction phase and performing regular checks for issues like hot spots and power degradation during operation, thereby providing a basis for system maintenance.

The detection capability of the equipment is influenced by several parameters. The quantum efficiency of the camera determines the signal acquisition capability, while the spatial resolution directly affects the accuracy of defect identification. The detection speed needs to match the production line cycle rate. In terms of environmental adaptability, measures to shield ambient light and control the operating temperature of the module are necessary, as the electroluminescence intensity exhibits a negative temperature coefficient characteristic.

Agricultural meteorological disasters pose enormous threats to agricultural production. During droughts, prolonged water shortage causes soil to dry out, stunting or even killing crops. In severe cases, large-scale crop failures or even total harvest losses occur, with scenes of cracked land and no...

Explosion - proof weather stations are meteorological monitoring devices specifically designed to operate in hazardous environments. With the development of industries such as manufacturing, military, and chemical, the demand for explosion - proof weather stations has been growing steadily. The main...

A hydropower station, a comprehensive engineering facility that converts hydropower energy into electrical energy, operates on the fundamental principle of utilizing water level drop (water level difference). As water flows from a higher to a lower elevation, its stored energy drives a turbine to ro...

This Portable Weather Station features portability, ease of use and high measurement accuracy. Integrating multiple meteorological elements, it is a movable observation system. Adopting a new-type integrated structural design with excellent craftsmanship, this design not only greatly simplifies the...